Needle shaped wollastonite powder, as an important industrial mineral raw material, has been widely used in various fields due to its unique needle shaped fiber structure and excellent physical and chemical properties. Here are 10 related topics, covering their characteristics, applications, processes, and market dynamics.

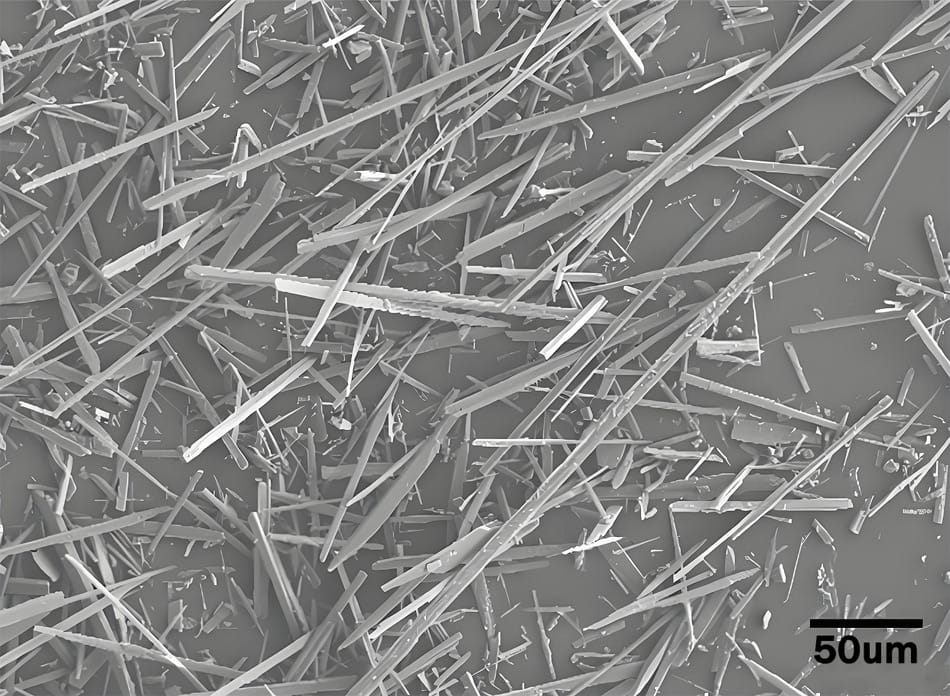

-Chemical composition and crystal structure:

The chemical formula of needle shaped wollastonite powder is CaSiO Ⅲ, with theoretical compositions of CaO 48.25% and SiO ₂ 51.75%. It belongs to the triclinic system, and the crystals are often needle shaped or fibrous, with a length to diameter ratio of 15:1 or more. This structure endows it with a unique strengthening mechanism.

-Physical performance indicators:

Its density is 2.78-2.91 g/cm ³, Mohs hardness is 4.5-5.0, melting point is 1540 ℃, thermal expansion coefficient is 6.5 × 10 ⁻⁶/℃ (20-800 ℃), whiteness can reach over 90%, and it does not contain crystal water. It is not easy to produce bubbles or cracks during processing.

-Chemical stability and functional characteristics:

Strong acid and alkali corrosion resistance, with a dissolution rate of less than 3% in 20% hydrochloric acid and less than 1.5% in 50% sodium hydroxide. At the same time, it has low moisture absorption and good electrical insulation properties (with a volume resistivity of up to 10 Ω· cm), suitable for electronic material applications.

-Industrial production and specification system:

The production process includes ore sorting, crushing, grinding, and surface modification. High quality raw materials must meet chemical indicators such as SiO ₂ ≥ 50% and CaO ≥ 45%. Mesh specifications such as 200-400 mesh are used for building materials, 800-1250 mesh are used for plastic and rubber, and over 1500 mesh are used for high-end coatings and electronic materials.

-Plastic industry application:

Adding 20-30% needle shaped wollastonite powder to engineering plastics such as PP and PA can increase the bending modulus by more than 40%, increase the hot deformation temperature by 15-20 ℃, and reduce equipment wear and surface defects of products compared to glass fiber.

-Application in the paint industry:

It can replace 10-15% titanium dioxide in latex paint without affecting the covering power. In anti-corrosion coatings, the sheet-like structure prolongs the penetration path of corrosive media. The ultrafine powder (such as 1250 mesh) can also improve the weather resistance of the coating. After QUV testing, the gloss retention rate remains above 90%.

-Ceramics and emerging field applications:

Adding 8-12% to ceramic glazes can reduce the firing temperature by 30-50 ℃, and adding 15-20% to the body can improve the drying strength; Emerging applications include lithium battery separator coatings (utilizing thermal stability), biodegradable plastics (improving modulus and degradation rate), and 3D printing materials (improving rheological properties).

-Surface modification technology:

By using silane coupling agents or stearic acid treatment, the interfacial bonding strength with polymer matrix can be significantly improved. The tensile strength and bending strength of the modified composite material can be increased by 3-5 times, optimizing its dispersibility in PVC and engineering plastics.

-Cost effectiveness and environmental benefits:

Replacing 30% glass fiber in plastics can reduce costs by 25-40%, replacing 15% titanium dioxide in coatings can save more than 20% of raw material costs, and the production energy consumption is only 1/8 of glass fiber. There is no wastewater or exhaust emissions, which is in line with the trend of green manufacturing.

-Market Trends and Future Directions:

The global market size is expected to exceed 1.5 billion US dollars by 2025, with development directions including surface modification technology (such as plasma treatment) and nanotechnology, and downstream applications extending to high-end fields such as new energy and biomedicine. The proportion of high value-added products in China is expected to increase to 40%.